The new model I’m currently building features an elevated neck. This improves comfort when reaching the higher register and allows the fingerboard’s natural contractions to act on the extended neck rather than the top.

Building

The woods I use include Brazilian Rosewood, Indian Rosewood, Bolivian Rosewood, Cocobolo, European Walnut, Plane (Platanus), Maple, Mahogany, Carob, and Guayubira for the back and sides. Spruce or Red Cedar for the tops. Ebony and Lignum Vitae for the fingerboards. Raulí for the neck. Brazilian or Indian Rosewood for the bridges.

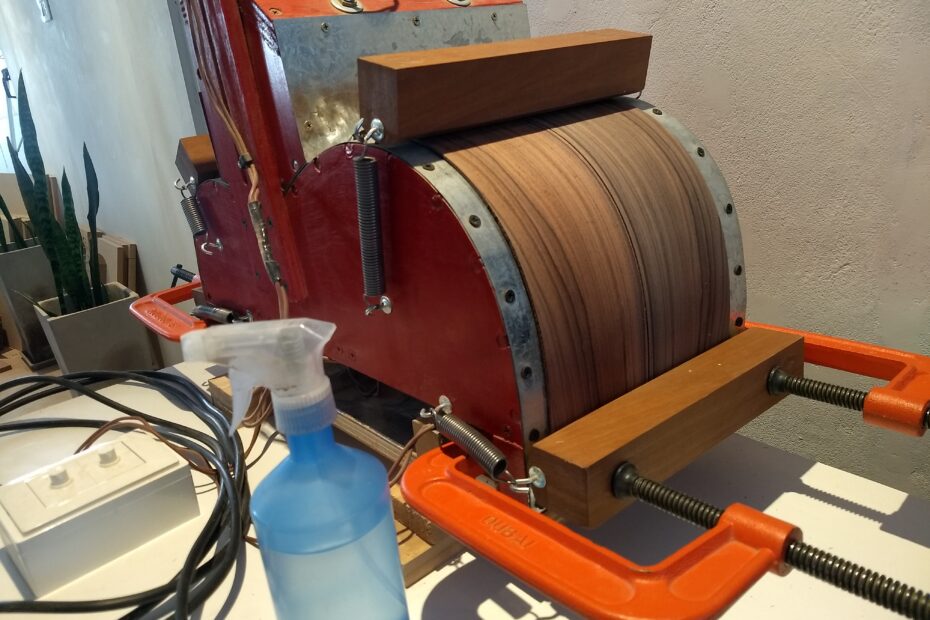

Here I show you how I bend the sides using a machine I built, which efficiently controls the temperature so the sides fit perfectly to the mold.

The decorations on the backs, sides, and headstocks are crafted in various ways, incorporating inlays of mother-of-pearl, bone, wood, or brass to make each guitar a unique work of art.

I make the necks from Raulí wood. This wood has proven itself in carpentry, possessing hardness superior to cedar and, above all, greater stability. Being a vital part of the instrument that requires stability and firmness, I choose woods that have been properly seasoned for at least 20 years to meet these conditions.

Selection of backs

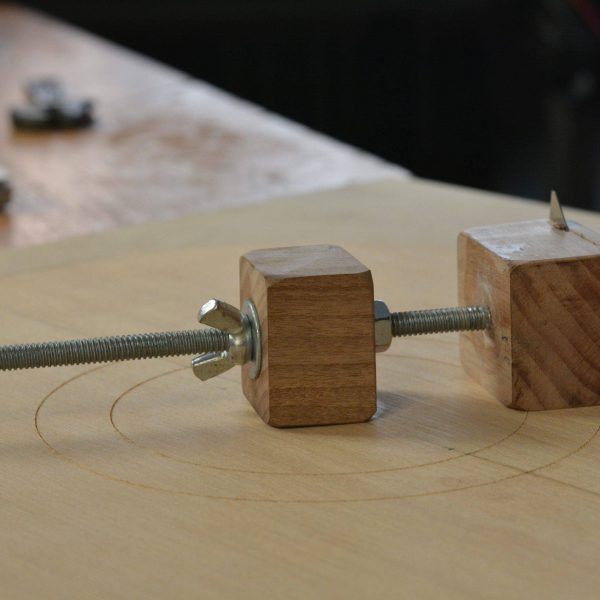

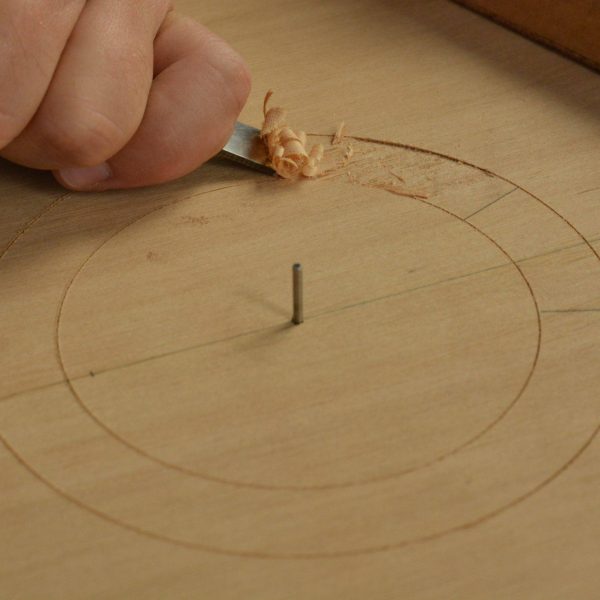

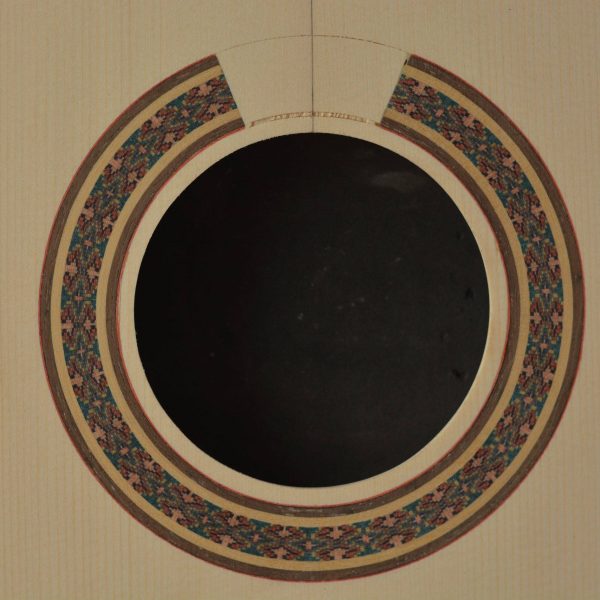

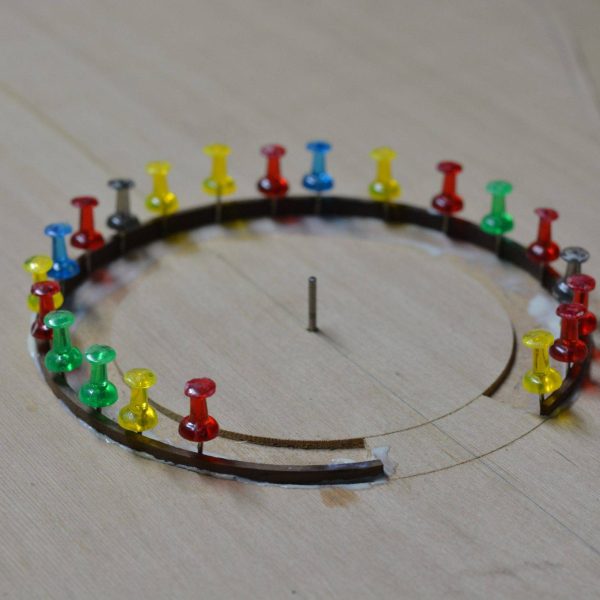

Construction of the Keller rosette

This is how I make handmade rosettes for all my instruments. It is a very laborious and rewarding task at the same time. The design is inspired by the "yarará", which inhabits the coasts and estuaries of the Paraná river that flows through my city, San Nicolás de los Arroyos.